How Big Is Electron Beam Machining Market?

Market Overview

The Electron Beam Machining Market, as per Credence Research, was valued at USD 734.5 million in 2024 and is projected to reach USD 1,161.9 million by 2032, at a CAGR of 5.9%. It benefits from rising demand for precision engineering across aerospace, automotive, and medical sectors. Its ability to machine intricate components with minimal thermal distortion supports adoption in high-performance applications. The trend toward miniaturization in electronics further drives demand for fine, accurate features. Technological advancements in electron beam generators and focusing systems enhance efficiency and expand applicability, making EBM a preferred choice for complex manufacturing processes.

Source: https://www.credenceresearch.com/report/electron-beam-machining-market

Market Drivers

Rising Demand for Precision Engineering in Key Industries

The Electron Beam Machining Market expands with increasing demand for high-precision components in aerospace, automotive, and medical industries. It handles hard-to-process materials with minimal distortion and produces intricate geometries efficiently. EBM improves production quality while reducing defects, ensuring tight tolerances for critical applications. Its ability to create durable, high-performance parts supports industry requirements for advanced machinery and aircraft systems. Adoption grows as companies seek precision solutions that align with strict regulatory and safety standards. It drives collaborations between manufacturers and suppliers to optimize machining capabilities and meet complex production needs.

Technological Advancements Fueling Adoption

The Electron Beam Machining Market benefits from continuous technological improvements in electron beam generators, focusing systems, and control software. It enhances machining accuracy, operational efficiency, and cost-effectiveness. High-speed and high-power EBM operations facilitate both prototyping and large-scale production. It reduces material waste, tool wear, and setup time, improving overall productivity. Adoption expands across sectors due to enhanced performance and versatility. It also supports the miniaturization trend in electronics by enabling fabrication of micro-scale components. These innovations increase reliability and attract new applications in aerospace, automotive, and medical industries, boosting market penetration.

Market Trends and Opportunities

Increasing Adoption in Aerospace and Automotive Sectors

The Electron Beam Machining Market is gaining traction in aerospace and automotive industries. It supports manufacturing of lightweight, high-strength components for engines, turbines, EVs, and advanced powertrains. It processes materials like titanium and high-strength steel while maintaining precision. EBM reduces production time and improves part performance. It facilitates creation of complex geometries that meet stringent safety standards. Companies adopt EBM to enhance competitiveness and reduce operational risks. The technology also opens opportunities for advanced aerospace and automotive components, enabling broader deployment in high-performance applications.

Miniaturization and Precision in Electronics Manufacturing

The Electron Beam Machining Market benefits from the miniaturization of electronic components. It produces semiconductors, sensors, and microprocessors with exceptional accuracy. It supports intricate circuit boards and high-density electronic assemblies. EBM enables fine-detail fabrication with minimal thermal impact. It offers advantages in reducing defects and improving product quality. Adoption expands in electronics, medical devices, and industrial applications. It creates opportunities for manufacturers to deliver high-precision solutions in emerging and established markets, meeting the increasing demand for compact and efficient electronic devices.

Market Challenges

High Equipment Costs and Technical Complexity

The Electron Beam Machining Market faces challenges from expensive equipment and complex operations. It requires advanced materials, specialized expertise, and robust infrastructure. Maintenance and calibration demand significant investment. It may restrict adoption among smaller manufacturers. Operational complexity increases with multi-material machining and high-precision applications. It also requires skilled personnel for setup and programming. These factors can slow technology adoption and limit regional expansion in developing economies.

Regulatory and Operational Constraints

The Electron Beam Machining Market contends with strict safety and regulatory standards. It must comply with international and national manufacturing guidelines. Energy consumption, thermal management, and beam control add operational challenges. It requires integration with existing production systems without compromising efficiency. Personnel training and technical support are essential for reliable operations. It faces scrutiny regarding environmental impact and safety in high-energy processes. Manufacturers must continuously innovate to overcome regulatory and operational constraints while maintaining market growth.

Regional Analysis

North America: Holds 35% market share, driven by aerospace, automotive, and medical device demand.

Europe: Accounts for 25% share, supported by advanced manufacturing infrastructure and key industry players.

Asia-Pacific: Represents 25% share, with fastest growth due to industrialization, electronics, and precision machining adoption.

Middle East & Africa: Holds 10% share, expanding with defense and industrial applications.

Latin America: Accounts for 5% share, driven by emerging manufacturing and industrial investments.

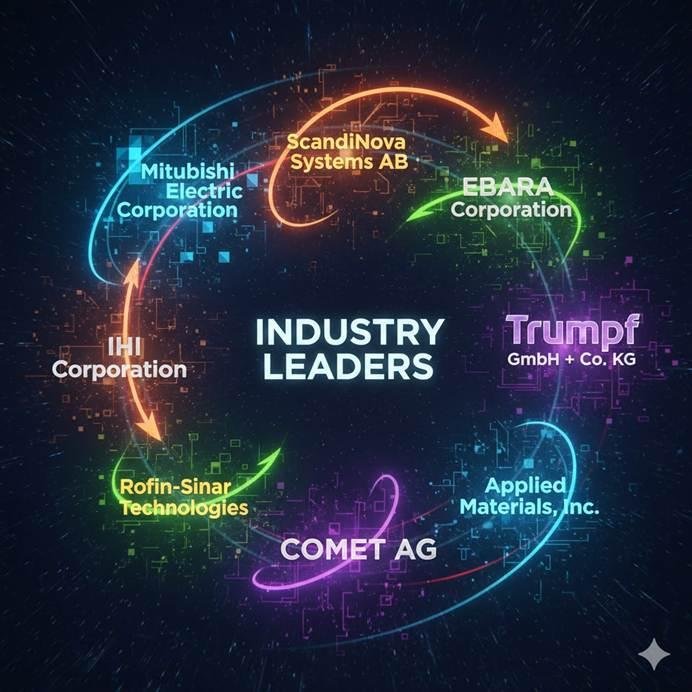

Key Players

Electron Beam Engineering, Inc.

Advanced Electron Beam Technologies

Mitsubishi Electric Corporation

ScandiNova Systems AB

EBARA Corporation

Trumpf GmbH + Co. KG

COMET AG

IHI Corporation

Rofin-Sinar Technologies

Applied Materials, Inc.

Go-To Market Strategy

The Electron Beam Machining Market emphasizes delivering precise, reliable, and cost-efficient solutions. It collaborates with aerospace, automotive, and electronics manufacturers to tailor systems for complex components. It invests in R&D for enhanced beam generators, focusing systems, and control software. It promotes modular, scalable designs for versatile applications. It leverages pilot testing, training, and technical support to boost adoption. It highlights efficiency, quality, and precision to differentiate offerings. It partners with regional distributors to expand market reach. It positions products as critical solutions for high-precision and high-value manufacturing sectors worldwide.

Recent Developments

2022: Electron Beam Engineering, Inc. implemented EBM for Inconel 718 aircraft engine components.

2023: Mitsubishi Electric enhanced EBM control systems for industrial and medical applications.

2023: COMET AG launched high-precision beam generators with improved focusing capabilities.

2024: Trumpf GmbH demonstrated large-scale EBM systems for aerospace component manufacturing.

2024: IHI Corporation expanded its R&D facility for advanced EBM equipment in Japan.

Future Outlook

The Electron Beam Machining Market will continue growing due to increasing demand for precision engineering and miniaturized components. It will expand across aerospace, automotive, electronics, and medical sectors. Adoption of high-power, high-speed EBM systems will increase to meet production efficiency needs. It will benefit from technological innovations in beam control and material handling. Market players will focus on modular, scalable solutions for multi-industry applications. It will strengthen collaborations with OEMs and technology providers. Continuous R&D will enhance precision, reduce costs, and improve reliability. It will drive global adoption in advanced manufacturing environments.

For full report : https://www.credenceresearch.com/report/electron-beam-machining-market

- Business

- Research

- Energy

- Art

- Causes

- Tech

- Crafts

- crypto

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness