Important Points for Efficient Plastic Spoon Mold Operation

Plastic spoon molds are widely used in the production of disposable and reusable spoons for food service and household applications.

Correct Installation and Alignment

Before starting production, ensure that the plastic spoon mold is properly installed in the injection molding machine. Check that all screws, bolts, and fixtures are tightened securely and that the mold is correctly aligned with the machine’s clamping system. Misalignment can lead to uneven filling, flash, or deformation of the spoons.

Temperature Control

Temperature is a critical factor in molding plastic spoons. Both the mold and the injected plastic must reach the appropriate temperature range. Excessive heat can cause warping, degradation, or surface defects, while low temperatures may result in incomplete filling or poor surface finish. Use accurate temperature control and regularly monitor conditions to maintain consistency.

Material Selection and Injection Parameters

Use the plastic materials specified for the mold, such as polystyrene (PS) or polypropylene (PP). Adjust injection pressure, speed, and cooling time according to the material’s characteristics and the mold design. Following the manufacturer’s recommended parameters reduces the risk of defects such as short shots, sink marks, or warping.

Cleaning and Maintenance

Regular cleaning of the mold is essential to remove plastic residues, dust, or debris. Inspect moving parts such as ejector pins and slides for wear, and apply lubrication if necessary. Routine maintenance ensures smooth operation, minimizes downtime, and extends the mold’s life.

When using plastic spoon molds, attention should be given to installation, temperature control, proper material and injection settings, and regular maintenance. Following these guidelines ensures efficient production and high-quality spoons.

https://www.food-container-mold.com/product/disposable-plastic-multi-grid-food-container-mould-series/square-four-gid-box-and-4-1-box-lid-thin-mould.html

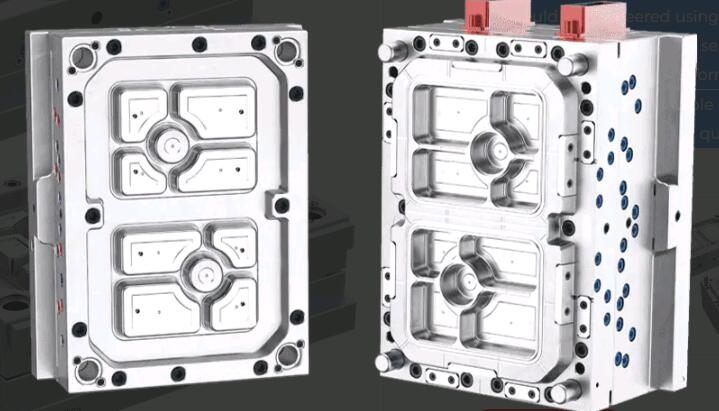

Our Disposable Plastic Disposable Plastic Square Four Grid Box And 4+1 Box & Lid Thin Mould is engineered using cutting-edge technology in high-precision plastic injection molding. This mold series specializes in producing plastic boxes and lids with exceptional sealing performance, ensuring the integrity and freshness of contents. Crafted from durable 2344 material, the product promises longevity and resilience, meeting stringent quality standards.

- Business

- Research

- Energy

- Art

- Causes

- Tech

- Crafts

- crypto

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness