Inverter Duty Motors Market Surges with Demand for Precision Control

Inverter Duty Motors Market grows with rising demand for energy-efficient, variable speed motors in industrial and commercial sectors during 2026–2030F.

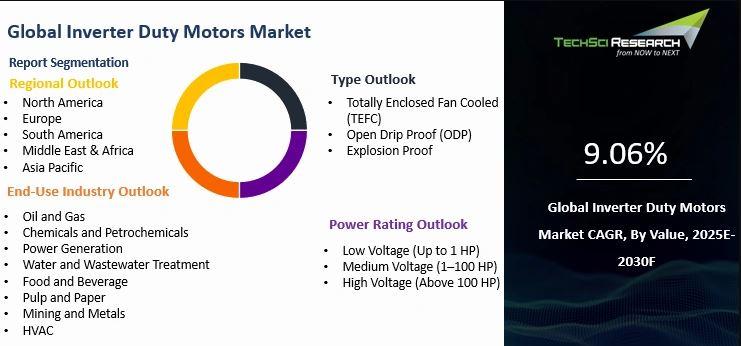

According to TechSci Research's report, “Inverter Duty Motors Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2020–2030F,” the Global Inverter Duty Motors Market stood at USD 5.26 billion in 2024 and is projected to reach USD 8.93 billion by 2030, growing at a CAGR of 9.06% during the forecast period. The market is witnessing significant growth, propelled by rapid industrialization, energy efficiency mandates, and surging demand across key end-use sectors such as oil & gas, manufacturing, and automotive.

One of the primary drivers for the market is the accelerating adoption of electric vehicles (EVs). Inverter duty motors play a crucial role in electric propulsion systems, offering precise speed and torque control that directly enhances energy efficiency and extends battery life. With global EV sales reaching 10.5 million units in 2023—a 55% increase over 2022, as per the International Council on Clean Transportation (ICCT)—the demand for high-performance inverter-compatible motors is surging. These motors offer efficiency improvements of 10–12%, potentially extending an EV’s driving range by 20–25 miles per charge. As manufacturers continue to scale EV production, inverter duty motors are emerging as an essential component in electrified mobility, aligning with global sustainability goals and emission-reduction mandates.

Furthermore, inverter duty motors are gaining traction due to their compatibility with Variable Frequency Drives (VFDs), which offer advanced control over motor operations. This makes them particularly suitable for applications that require varying speeds, high torque, and energy savings. In industries where precise motion control is essential—such as textiles, packaging, and process automation—these motors are increasingly preferred over standard motors. Their robust insulation, enhanced cooling systems, and thermal protection features ensure reliable performance in demanding conditions.

However, the market also faces technical challenges, most notably harmonics, electrical noise, and electromagnetic interference (EMI). These are common issues in systems powered by VFDs, which rapidly switch voltages to control motor speed. Such switching generates high-frequency harmonics that can affect nearby electronic equipment, degrade power quality, and lead to equipment failure or inefficient operations. This is particularly problematic in sensitive environments such as data centers, hospitals, and precision manufacturing units. Even though inverter duty motors are designed to withstand thermal and electrical stresses, the broader system’s vulnerability to harmonics requires additional components like line reactors, EMI filters, and shielded cables, which increase the system's overall cost and complexity.

Moreover, compliance with international standards like IEC 61800-3 and IEEE 519, which regulate harmonics and EMI emissions, adds to the responsibility of manufacturers and users alike. Failure to meet these standards can result in system malfunction, regulatory penalties, or costly redesigns. In many cases, end-users lack the expertise to conduct thorough harmonic analysis or proper installation practices, leading to issues only discovered after commissioning. To mitigate these challenges, market players are emphasizing plug-and-play solutions, comprehensive installation guidance, and integrated harmonic suppression features to ensure seamless adoption across industries.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the " Global Inverter Duty Motors Market"

https://www.techsciresearch.com/report/inverter-duty-motors-market/29622.html

End-Use Industry Insight

Among the various end-use industries, the Oil and Gas sector accounted for the largest market share in 2024 and is expected to maintain its dominance through 2030. This is largely attributed to the critical role inverter duty motors play in high-load applications such as pumps, compressors, conveyors, and ventilation systems, which are integral to upstream, midstream, and downstream operations. The motors’ ability to handle variable speed and fluctuating load conditions makes them ideal for environments characterized by extreme temperatures, pressures, and operational volatility.

With rising global energy demand, the sector is under pressure to increase productivity while minimizing environmental impact. Inverter duty motors enable energy optimization and system flexibility, which are vital for reducing operational costs and emissions. Moreover, modernization efforts in refineries, expansion of pipeline infrastructure, and offshore exploration activities further fuel the need for efficient and reliable motor systems. Compared to other segments such as food & beverage, chemicals, and HVAC, the oil and gas industry presents more capital-intensive, continuous-operation settings, requiring motors with higher durability and performance reliability.

Regional Insight

Europe emerged as the fastest-growing region in the Inverter Duty Motors Market in 2024, and this momentum is expected to continue through the forecast period. This regional growth is driven by stringent energy efficiency regulations, ongoing investments in smart manufacturing, and a robust push towards industrial automation and carbon neutrality. The European Union’s Ecodesign and Energy Efficiency Directives mandate the adoption of high-efficiency motor systems, pushing industries to transition from conventional motors to inverter-compatible alternatives.

Countries like Germany, France, Italy, and the Netherlands are at the forefront of implementing Industry 4.0, integrating intelligent control systems with energy-efficient machinery. Inverter duty motors, with capabilities such as variable speed control, remote diagnostics, and real-time energy monitoring, are essential to the digital transformation of manufacturing and processing industries. Additionally, Europe’s growing investments in renewable energy and green building initiatives are bolstering the demand for inverter duty motors in sectors such as wind power, wastewater treatment, and sustainable construction.

The regional market also benefits from a strong presence of OEMs, technological innovation hubs, and high R&D investments. Companies in the region are retrofitting aging infrastructure with energy-efficient motor systems to meet carbon reduction goals and enhance operational efficiency. The combination of policy support, technological innovation, and industrial modernization positions Europe as a key growth engine in the global inverter duty motors landscape.

Conclusion:

The global Inverter Duty Motors Market is poised for strong expansion, driven by factors such as EV adoption, energy efficiency demands, and modernization across various sectors. While challenges like harmonics and EMI persist, ongoing innovation, regulatory compliance, and increasing awareness about advanced motor systems are expected to fuel market adoption. With major opportunities in the oil & gas industry and high growth prospects in Europe, the inverter duty motors market is set to play a pivotal role in the next wave of energy-efficient and intelligent motor technologies.

Key market players in the Global Inverter Duty Motors market are: -

ABB Ltd.

Siemens AG

WEG S.A.

Regal Rexnord Corporation

Nidec Corporation

Toshiba International Corporation

Rockwell Automation, Inc.

General Electric Company

Kirloskar Electric Company Ltd.

Schneider Electric SE

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=29622

Customers can also request for 10% free customization on this report.

“The inverter duty motors market is poised for robust growth in the future, driven by increasing demand for energy-efficient and variable speed motor solutions across industries such as oil and gas, water treatment, manufacturing, and HVAC. Advancements in automation, rising adoption of Industry 4.0, and strict energy efficiency regulations are compelling industries to replace traditional motors with inverter duty variants.

Additionally, growing investments in infrastructure, electric vehicles, and renewable energy will further expand market opportunities. As industries prioritize operational efficiency, digital control, and sustainability, the inverter duty motors market is expected to witness sustained expansion globally in the coming years.” said Mr. Karan Chechi, Research Director of TechSci Research, a research-based Global management consulting firm.

“Inverter Duty Motors Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented By Type (Totally Enclosed Fan Cooled (TEFC), Open Drip Proof (ODP), Explosion Proof), By Power Rating (Low Voltage (Up to 1 HP), Medium Voltage (1–100 HP), High Voltage (Above 100 HP)), By End-Use Industry (Oil and Gas, Chemicals and Petrochemicals, Power Generation, Water and Wastewater Treatment, Food and Beverage, Pulp and Paper, Mining and Metals, HVAC), By Region & Competition, 2020-2030F,” has evaluated the future growth potential of Global Inverter Duty Motors Market and provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in Global Inverter Duty Motors Market.

Contact

TechSci Research LLC

420 Lexington Avenue,

Suite 300, New York,

United States- 10170

M: +13322586602

Email: sales@techsciresearch.com

Website: https://www.techsciresearch.com

- Business

- Research

- Energy

- Art

- Causes

- Tech

- Crafts

- crypto

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness