"What is the Future of the Robotic Palletizers Market from 2024 to 2032?"

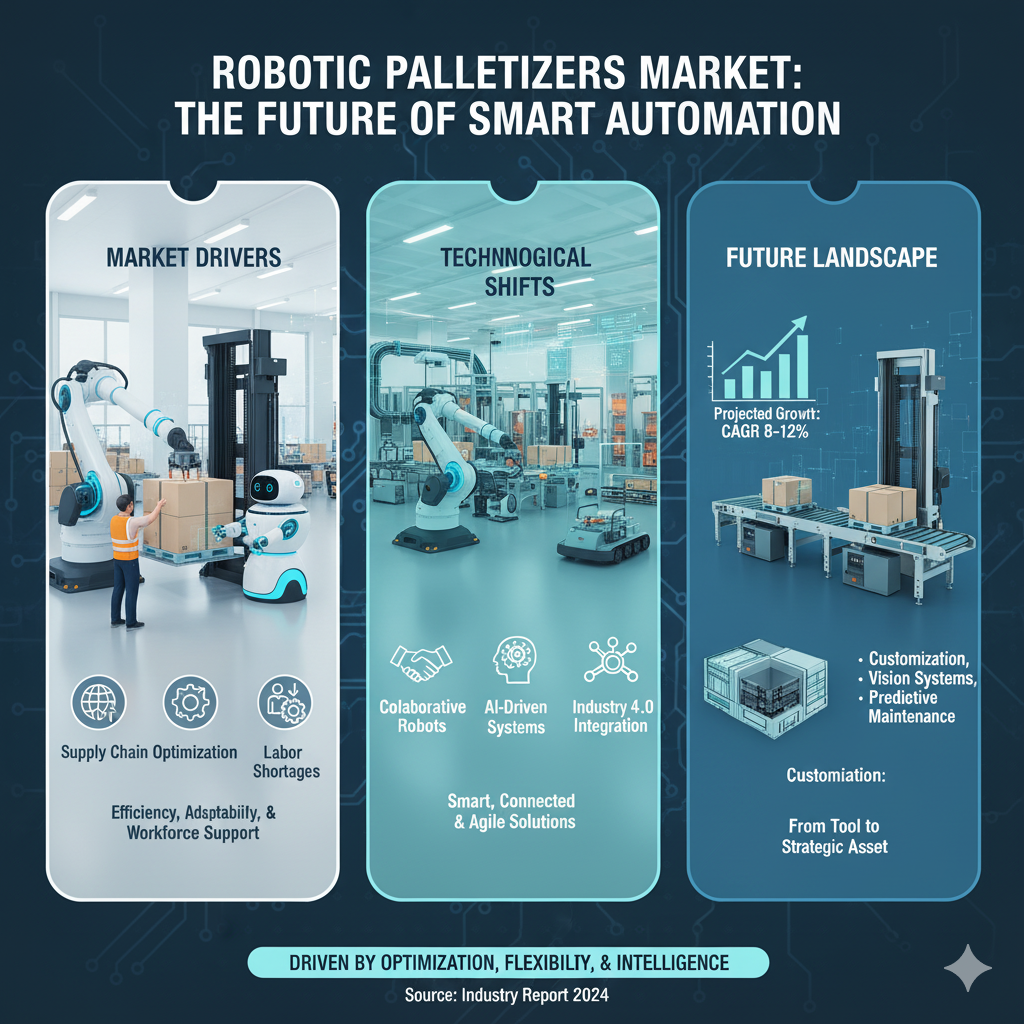

The robotic palletizers market is poised for a period of robust and transformative growth from 2024 to 2032. Moving beyond a simple automation tool, robotic palletizing is becoming an integral component of the smart, connected, and agile factory. The market will be driven by the unrelenting pressure for supply chain optimization, the need for flexibility in manufacturing, and the critical challenge of labor shortages. The era of "one-size-fits-all" palletizing is over, making way for a future dominated by collaborative robots, advanced AI-driven systems, and seamless integration with Industry 4.0 infrastructure.

According to Credence Research The robotic palletizers market size was valued at USD 2,643 million in 2024 and is anticipated to reach USD 3947.4 million by 2032, at a CAGR of 5.14 % during the forecast period (2024-2032).

Source: https://www.credenceresearch.com/report/robotic-palletizers-market

Market Overview and Growth Projections

- Current Market State (2024): The market is in a mature growth phase. Traditional articulated robotic arms dominate in high-speed, high-volume applications (e.g., beverage, food, and pharmaceuticals). Adoption is widespread in developed economies and is accelerating rapidly in emerging markets.

- Growth Forecast (2024-2032): The market is expected to grow at a Compound Annual Growth Rate (CAGR) of approximately 5-7%, with some analysts projecting even higher figures depending on the region and segment. This would see the market value increase significantly from its 2023 base, potentially reaching well over USD 2.5 billion by 2032.

- Key Growth Drivers: The expansion will not be linear but rather accelerated by several converging macro and micro-economic factors.

Primary Growth Drivers and Enablers

a) The Chronic Labor Shortage and Rising Labor Costs:

This remains the most potent driver. Palletizing is a physically demanding, repetitive, and high-injury-risk job. Companies across the globe find it increasingly difficult to attract and retain a workforce for these roles. Robots offer a reliable, 24/7 solution that is immune to fatigue, turnover, and the rising costs of wages and benefits.

b) Supply Chain Resilience and E-commerce Demands:

The post-pandemic world has underscored the need for resilient and flexible supply chains. E-commerce requires faster order fulfillment, smaller batch sizes, and more mixed-SKU pallets—a task incredibly challenging for manual labor. Robotic palletizers, especially flexible and vision-guided ones, are essential for warehouses and distribution centers to adapt to this new reality.

c) The Push for Operational Efficiency and Cost Reduction:

Robots optimize the entire logistics chain. They:

- Increase Throughput: Operate at consistent, high speeds.

- Reduce Product Damage: Precise and gentle handling minimizes losses.

- Optimize Space: Can be deployed in tighter spaces and can build denser, more stable pallets.

- Lower Energy Costs: Modern robots are more energy-efficient than ever.

d) Advancements in Core Technology:

The technology itself is becoming more accessible and capable:

- Improved Vision Systems: 3D vision and deep learning allow robots to identify, locate, and handle a vast array of package types, sizes, and conditions, even in unstructured environments.

- Easier Programming & Simulation: Offline programming (OLP) and user-friendly graphical interfaces drastically reduce integration time and the need for highly skilled robot programmers.

- Declining Total Cost of Ownership (TCO): While the initial investment is significant, the declining cost of components and the clear ROI in labor savings and efficiency make the business case stronger each year.

Key Trends Shaping the Market (2024-2032)

a) The Proliferation of Collaborative Robotic Palletizers (Cobots):

This will be one of the most significant trends. Collaborative palletizers, designed to work safely alongside humans without extensive safety fencing, are ideal for Small and Medium-sized Enterprises (SMEs). They address the key barriers of cost, space, and flexibility, allowing businesses to automate palletizing without a complete facility overhaul.

b) Artificial Intelligence (AI) and Machine Learning (ML) Integration:

AI will move robots from automated to autonomous.

- Predictive Palletizing: AI algorithms will analyze order data to optimize pallet patterns for stability, space utilization, and specific delivery routes.

- Anomaly Detection: ML models will learn to identify damaged packages, mislabelled products, or pattern deviations in real-time, triggering automatic rejection or alerts.

- Self-Optimization: Systems will continuously learn and adjust their grip strength, speed, and path planning to maximize efficiency and minimize product damage.

c) The Rise of the "Plug-and-Play" and Mobile Palletizing Solution:

Vendors are increasingly offering standardized, pre-engineered cells that can be deployed quickly with minimal customization. Furthermore, the concept of mobile palletizing robots autonomous mobile manipulators (AMRs with arms) will gain traction for dynamic warehouse environments where the palletizing point is not fixed.

d) Software is King: The Palletizing Ecosystem:

The value will increasingly shift from the hardware (the robot arm) to the software that controls it. Advanced Palletizing Programming Software (PPS) and Fleet Management systems will allow for centralized control of multiple palletizing cells, providing real-time data on performance, maintenance needs, and throughput.

e) Sustainability-Driven Adoption:

Companies with strong Environmental, Social, and Governance (ESG) goals will adopt robotics to:

- Reduce waste from product damage.

- Optimize pallet patterns to minimize transportation trips (lower carbon footprint).

- Create safer workplaces, improving their "Social" metrics.

Market Segmentation Insights

- By Type:

- Articulated Robots: Will continue to dominate in high-volume, high-speed industries.

- Collaborative Robots (Cobots): The fastest-growing segment, capturing the SME market and low-to-medium throughput applications.

- Gantry/Cartesian Robots: Will remain relevant for very heavy payloads or applications requiring massive reach across a wide area.

- By Application:

- Traditional Industries (Food & Beverage, Pharmaceuticals, Consumer Goods): These will remain the core users, focusing on upgrades to smarter, more connected systems.

- E-commerce & Logistics: This will be the star growth segment. The need for sorting, singulation, and mixed-SKU palletizing in distribution centers will drive massive investment.

- Chemicals and Construction Materials: Steady adoption for handling heavy, hazardous, or non-uniform bags and sacks.

Regional Market Analysis

- North America & Europe: Mature but growing markets. Driven by high labor costs, stringent safety regulations, and advanced manufacturing infrastructure. Growth will come from modernizing existing systems and adoption by SMEs.

- Asia-Pacific (APAC): The dominant and fastest-growing market. Led by China, Japan, South Korea, and emerging Southeast Asian nations. Massive manufacturing output, rapid industrialization, government initiatives like "Made in China 2025," and rising labor costs are fueling an automation boom.

- Latin America and Middle East & Africa: Emerging markets with significant potential. Growth will be slower but steady, initially concentrated in large multinational corporations and specific export-oriented industries like mining and agriculture.

Challenges and Restraints

- High Initial Capital Investment: This remains the primary barrier, especially for small businesses.

- Integration Complexity: Integrating robots with existing Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems can be challenging.

- Skills Gap: A shortage of workers who can operate, maintain, and troubleshoot advanced robotic systems persists.

- Limitations with Unstructured Environments: While improving, robots can still struggle with highly variable, deformable, or randomly oriented items compared to the human hand-eye coordination.

Conclusion: The 2032 Outlook

By 2032, robotic palletizing will be the de facto standard for any company involved in manufacturing, warehousing, or logistics of scale. The market will be characterized by:

1. Ubiquity and Accessibility: Robots will no longer be a luxury for large corporations but a standard tool accessible to businesses of all sizes.

2. Intelligent and Adaptive Systems: AI-driven palletizers will be self-optimizing nodes within a fully digitalized supply chain.

3. The Human-Robot Collaboration Model: The role of humans will shift from manual palletizing to system supervision, maintenance, exception handling, and continuous improvement of the automated processes.

In essence, the future of the robotic palletizers market is not just about replacing a manual task; it's about creating a fundamentally more responsive, efficient, and intelligent logistics backbone for the global economy.

Source: https://www.credenceresearch.com/report/robotic-palletizers-market

- Business

- Research

- Energy

- Art

- Causes

- Tech

- Crafts

- crypto

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness