Hand Laser Welder – Revolutionizing Metal Welding Precision and Efficiency

The hand laser welder has become one of the most practical tools in modern metalworking, offering exceptional accuracy, portability, and performance across various industries. Whether used in manufacturing, repair, or fabrication, this device allows operators to weld metals with pinpoint precision and minimal effort. Over the past decade, the evolution of laser welding technology has significantly improved productivity, reduced processing times, and opened new possibilities for both large-scale industrial operations and small workshops.

The Growing Role of Hand Laser Welders in Modern Industry

Welding remains an essential part of metal fabrication, but traditional methods such as TIG or MIG welding often demand considerable skill, experience, and setup time. The hand laser welder changes this scenario by introducing a more intuitive and flexible approach to metal joining. The machine allows precise control of energy output and focus, enabling cleaner, faster, and more consistent welds.

Industries such as automotive, aerospace, electronics, and custom manufacturing increasingly rely on laser-based systems for their ability to handle thin materials, delicate joints, and complex geometries. The handheld laser welder offers all these benefits while maintaining mobility — allowing operators to work on-site or in confined spaces where conventional equipment would be impractical.

Technology Behind the Hand Laser Welder

At its core, a hand laser welder uses a focused laser beam to fuse metal surfaces together. The beam generates intense heat concentrated on a small area, causing the metal to melt and form a solid joint when cooled. Fiber lasers are most commonly used in these systems due to their efficiency, stability, and long lifespan.

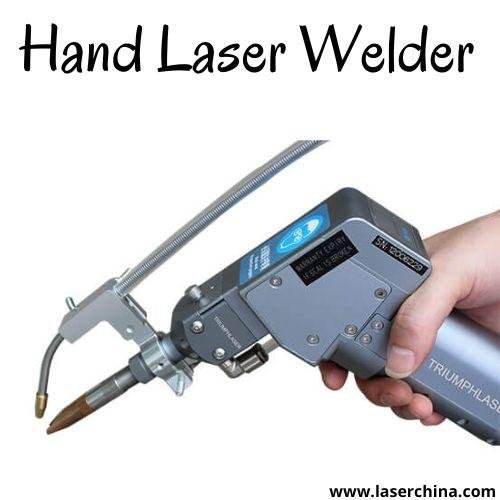

The handheld design incorporates a lightweight, ergonomic welding gun connected to a main laser source. A wire feeder can be attached if additional filler material is required. Integrated safety features, real-time temperature monitoring, and touch-screen controls allow the operator to maintain complete command over the welding process.

Another critical component is the cooling system, which keeps the laser source stable during continuous operation. Many models use air or water cooling depending on power output and operational demands.

Applications of Hand Laser Welders

The hand laser welder has versatile applications across a range of materials and industries:

-

Automotive Manufacturing and Repair – Ideal for joining stainless steel, aluminum, and mild steel components in car frames, exhausts, and bodywork repairs.

-

Aerospace Engineering – Used for precision joints in lightweight alloys and high-strength materials where accuracy is vital.

-

Jewelry and Artisanal Work – Provides delicate control for fine metal designs without causing heat distortion or surface damage.

-

Electronics and Electrical Fabrication – Enables micro-welding of components, sensors, and casings with consistent performance.

-

Maintenance and On-Site Repairs – The portability of a handheld unit allows technicians to conduct welding at remote or difficult-to-reach locations.

Each of these uses benefits from the laser’s concentrated energy and minimal heat-affected zone, which helps maintain the original structure and appearance of the material.

The Shift Toward Portable Laser Welding Solutions

As manufacturing transitions toward automation and precision, demand for compact, mobile, and efficient tools continues to grow. The hand laser welder fits perfectly into this trend. Its design allows even small workshops to integrate laser technology without the need for expensive robotic systems or dedicated welding stations.

The lightweight structure makes it practical for operators to work long hours without fatigue. It can weld various thicknesses, from thin sheets to moderate metal plates, without the need to switch tools or adjust complex setups.

Many modern versions also integrate smart systems for quick power calibration, multi-material presets, and enhanced safety controls. This adaptability has made the hand laser welder a standard piece of equipment in both professional and industrial settings.

Comparing Traditional and Laser-Based Welding

Traditional arc welding techniques have long served as the foundation of metal joining, but they involve significant challenges such as deformation, spatter, and post-processing work. The hand laser welder addresses many of these issues through its concentrated energy delivery. The beam’s small diameter produces a narrow, deep weld with minimal distortion and no contact with the workpiece surface.

This non-contact approach also eliminates the need for consumables like electrodes or shielding gases in certain cases, depending on the material being processed. As a result, the overall workflow becomes cleaner, faster, and more controlled.

Quality and Precision in Every Weld

A key factor behind the growing use of hand laser welders is their unmatched precision. The narrow beam ensures high-quality seams even in thin or delicate materials. By adjusting power levels and beam parameters, the operator can fine-tune the weld depth and width to suit each task.

Laser welding minimizes the heat-affected zone, which helps maintain the original mechanical and chemical properties of the base material. This is particularly important for industries that demand reliability and structural integrity, such as medical device manufacturing and precision engineering.

Additionally, modern handheld units often come with visual guidance systems that assist the welder in maintaining consistent alignment and distance. This technology reduces errors and enhances repeatability, ensuring that each weld meets exacting standards.

Sustainability and Energy Efficiency

The global focus on energy efficiency and environmental responsibility has driven many manufacturers to adopt laser-based solutions. The hand laser welder aligns well with these goals due to its low energy consumption, minimal waste, and clean processing. Unlike traditional welding, it produces very little smoke or debris, reducing the need for ventilation systems and post-cleaning operations.

Because it operates efficiently and with minimal consumables, it also lowers long-term operating costs. This sustainability factor is increasingly appealing to industries aiming to reduce carbon footprints while maintaining productivity.

The Economic Impact on Manufacturing

The integration of hand laser welders in production environments has led to measurable improvements in both cost and efficiency. Shorter setup times, reduced rework, and consistent weld quality translate directly into financial savings.

For small and medium-sized enterprises (SMEs), adopting this technology enables them to compete with larger manufacturers by delivering professional-grade results with less investment. The modular and scalable nature of handheld systems allows workshops to expand their capabilities as demand grows.

Operator Experience and Training

Although laser welding may sound complex, modern hand laser welders are designed for simplicity and user comfort. Most systems feature digital interfaces with preset modes for different materials and thicknesses. Operators can switch between modes, adjust power, and monitor system performance from a single touchscreen.

Training requirements are minimal compared to traditional welding, as the process is more intuitive and automated. The reduced learning curve makes it suitable for operators of varying experience levels, allowing companies to onboard staff quickly and maintain consistent production.

Integration with Automation and Robotics

While handheld systems emphasize mobility, they can also be integrated into semi-automated setups for batch production. The same hand laser welder technology can be adapted into robotic arms or CNC systems for continuous operation. This hybrid approach allows manufacturers to benefit from both flexibility and automation, making laser welding a core part of modern fabrication lines.

Safety and Operation

Safety remains a top priority when using laser equipment. Every hand laser welder includes protective measures such as interlocks, laser shielding, and emergency stop mechanisms. Operators are required to wear laser-safe goggles to protect their eyes from reflected beams.

The equipment itself is built with multiple layers of protection, ensuring safe operation even in busy environments. Regular maintenance, such as cleaning the lens and checking the cooling system, ensures long-term stability and consistent results.

Final Thoughts

The hand laser welder represents a new era in precision welding. Its combination of portability, efficiency, and adaptability makes it a cornerstone of modern metalworking. From intricate repairs to large-scale manufacturing, this technology delivers consistent results while simplifying the welding process. As industries continue to evolve, the hand laser welder will remain a vital tool for achieving higher standards of quality, sustainability, and productivity in metal joining applications.

- Business

- Research

- Energy

- Art

- Causes

- Tech

- Crafts

- crypto

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness