Key Varieties of Plastic Bumper Moulds

Plastic bumper moulds are essential tools in automotive manufacturing, used to shape bumpers from thermoplastic materials. These moulds must meet high standards of precision, durability, and surface quality.

Single-Stage Injection Moulds

Single-stage injection moulds are designed to produce a complete bumper in one molding cycle. This type of mould offers simplified operations and is suitable for smaller production runs or standard bumper designs. While easier to maintain, single-stage moulds may have limitations in producing complex shapes or multi-layered bumpers.

Multi-Component Moulds

Multi-component moulds allow the production of bumpers with different materials or layers, such as rigid backing and soft outer skin. These moulds integrate several injection points and require precise timing and coordination. Multi-component moulds are commonly used for modern bumpers that combine aesthetics with impact resistance and safety features.

Modular or Segmented Moulds

Modular moulds consist of interchangeable sections that can be reconfigured for different bumper models or versions. This flexibility reduces tooling costs and production downtime when changing vehicle designs. Segmented moulds are particularly useful for manufacturers producing multiple car models with similar bumper dimensions.

High-Precision and Surface-Finish Moulds

Some plastic bumper moulds are designed specifically to achieve high-quality surface finishes, such as glossy coatings or detailed textures. These moulds require precise machining and polishing, as well as careful control of injection parameters. They are typically used for premium vehicles or bumpers with complex visual designs.

https://www.bumpermould.net/product/bumper-mould/plastic-front-bumper-for-bmw-x1.html

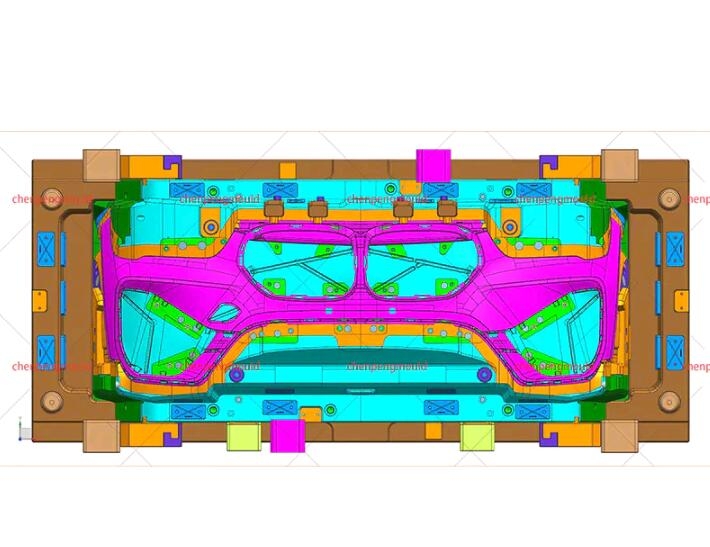

Mould Name BMW X1 Car Front Bumper Chin Mould

Material PP+EPDM

Bumper Size 1900*610*560mm

Steel For Cavity &. Core P20

Mould Base C45

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO

- Business

- Research

- Energy

- Art

- Causes

- Tech

- Crafts

- crypto

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness