What Custom Features Matter In A Precision Stamping Mold?

A Precision Stamping Mold sits at the center of motor core production. It influences how smoothly machines run, how often tools need adjustment, and how flexible a production line can be when product models change. For buyers searching online, the real question is not about theory, but how a mold behaves during real shifts on the shop floor.

How mold structure affects production rhythm

One key concern is whether a single mold can handle multiple product layouts. In motor manufacturing, frequent mold changes slow down schedules and increase internal coordination.

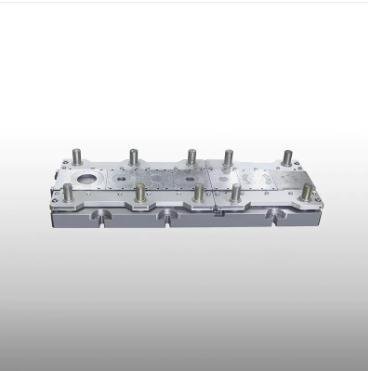

A precision progressive stamping die with a double-row structure helps address this issue. For example, a 155 double-row design using a three-slot stator layout and a two-slot rotor layout allows different products to be produced without switching molds. This approach improves mold utilization and helps factories manage development spending during model updates.

This kind of Precision Stamping Mold setup supports smoother transitions between product types, especially for factories running mixed orders.

What customization really means for buyers

Customization is not just about size. A Precision Stamping Mold Company is often evaluated by how well it adapts to motor core details provided by customers.

In practice, stamping molds may need to process stator and rotor laminations from Φ12 to Φ720mm. Functional requirements often include self-locking structures, skewed slots, or punched step holes within a defined diameter range. Buyers usually look for flexibility in mold layout, such as single-row, double-row, or multi-row options, depending on output targets and press conditions.

Forming processes also matter. Straight stacking with internal riveting, skew slot internal riveting, and large rotary internal riveting each suit different motor designs. A Precision Stamping Mold that supports these options helps buyers avoid redesigning tools when specifications evolve.

Why buyers look closely at the company behind the mold

Choosing a Precision Stamping Mold Company is rarely about the mold alone. Buyers pay attention to communication speed, drawing review ability, and how practical the technical feedback feels.

Factories prefer partners who can work directly from drawings and samples, identify potential issues early, and suggest mold structures that align with real production flow. This reduces back-and-forth and shortens the time between design approval and shop-floor use.

A company experienced in motor core stamping understands how small design details affect stacking behavior, lamination alignment, and long-term tool stability.

Buyers usually compare more than uthe nit cost. They consider how often molds need adjustment, how many product variations one tool can cover, and how easily the mold fits into existing presses.

A well-designed Precision Stamping Mold supports continuous operation and reduces interruptions caused by frequent tooling changes. Over time, this approach helps factories maintain consistent output without adding complexity to production planning.

- Business

- Research

- Energy

- Art

- Causes

- Tech

- Crafts

- crypto

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness