Best TDR for PCB Manufacturing: How Precision Testing Ensures Signal Integrity and Reliable Circuit Performance

In today’s high-speed electronics industry, signal integrity is everything. As PCB designs become more compact and complex, manufacturers must rely on advanced testing methods to ensure flawless performance. One of the most critical tools in this process is Time Domain Reflectometry (TDR). Choosing the Best TDR for PCB manufacturing helps detect impedance mismatches, trace defects, and signal loss before products reach the market.

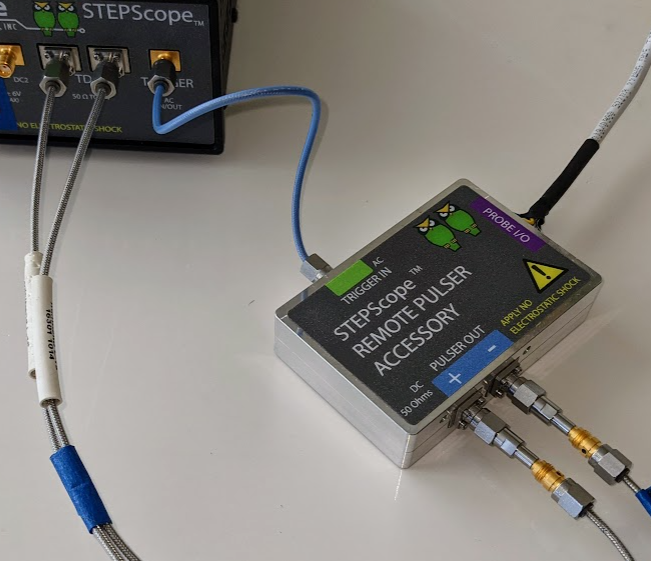

TDR works by sending a fast electrical pulse through a PCB trace and analyzing reflections caused by impedance changes. These reflections reveal issues such as open circuits, shorts, via defects, or incorrect trace widths. For multilayer and high-frequency PCBs, this level of precision is essential to meet modern performance standards.

At BitWise Laboratories, advanced PCB testing solutions are designed to meet the evolving demands of electronics manufacturers. With high-accuracy TDR testing, engineers can validate controlled impedance traces, differential pairs, and high-speed signal paths with confidence. This ensures that PCBs used in telecommunications, automotive electronics, medical devices, and aerospace systems perform reliably under real-world conditions.

Using the right TDR solution also reduces production costs. Early detection of defects minimizes rework, scrap, and field failures. It helps manufacturers maintain consistent quality while accelerating time-to-market. Whether it’s prototype validation or large-scale production testing, TDR plays a vital role in maintaining design integrity.

Another advantage of selecting the Best TDR for PCB manufacturing is compliance with industry standards. Accurate impedance measurements help meet IPC and customer-specific requirements, ensuring PCBs are accepted across global markets. This is especially important for high-speed digital and RF applications where even small variations can cause major performance issues.

It focuses on precision, reliability, and repeatability in PCB testing. Their expertise in TDR-based analysis allows manufacturers to confidently verify signal paths, optimize designs, and deliver high-quality boards. By integrating advanced testing early in the production cycle, businesses can improve yield, enhance product reliability, and build long-term trust with customers.

In a competitive electronics landscape, investing in accurate TDR testing is not optional—it’s essential for producing high-performance PCBs that meet today’s demanding technological standards.

For more visit us: https://bitwiselabs.com/

- Business

- Research

- Energy

- Art

- Causes

- Tech

- Crafts

- crypto

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness