The Rise of Lightweight Engineering in Aerospace 3D Printing

Lightweight engineering is a top priority in modern aerospace design. Reducing the mass of aircraft parts without compromising strength leads to higher efficiency and lower emissions. 3D printing has become the ideal technology to achieve this goal.

The US Aerospace 3D Printing Market is seeing growing investment in material development and process optimization aimed at lightweight production. Engineers are creating structures with internal lattices that maintain strength while drastically cutting weight.

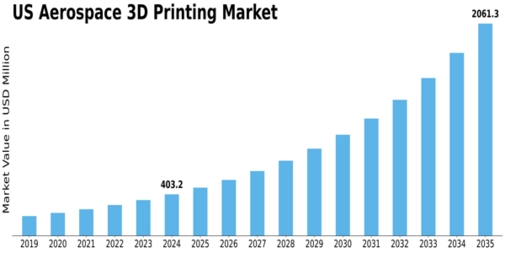

Market Size and Analysis

As indicated by current market analysis, the industry has expanded significantly, with size increasing across multiple aerospace domains. Additive manufacturing supports low-volume production, ideal for complex aircraft components.

Trends in Material and Design

Emerging trends include the use of titanium, composite materials, and multi-material printing. These advancements allow manufacturers to achieve weight reduction targets while maintaining durability and safety.

Future Forecast

The forecast expects continued research into nanocomposites and high-performance polymers that will further reduce aircraft weight. Lightweight 3D-printed components will soon become standard across aerospace platforms.

FAQs

1. Why is lightweight engineering important for aerospace?

It enhances fuel efficiency, increases payload capacity, and reduces environmental impact.

2. Which materials are most used in aerospace 3D printing?

Advanced metals, composite materials, and heat-resistant thermoplastics.

- Business

- Research

- Energy

- Art

- Causes

- Tech

- Crafts

- crypto

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness